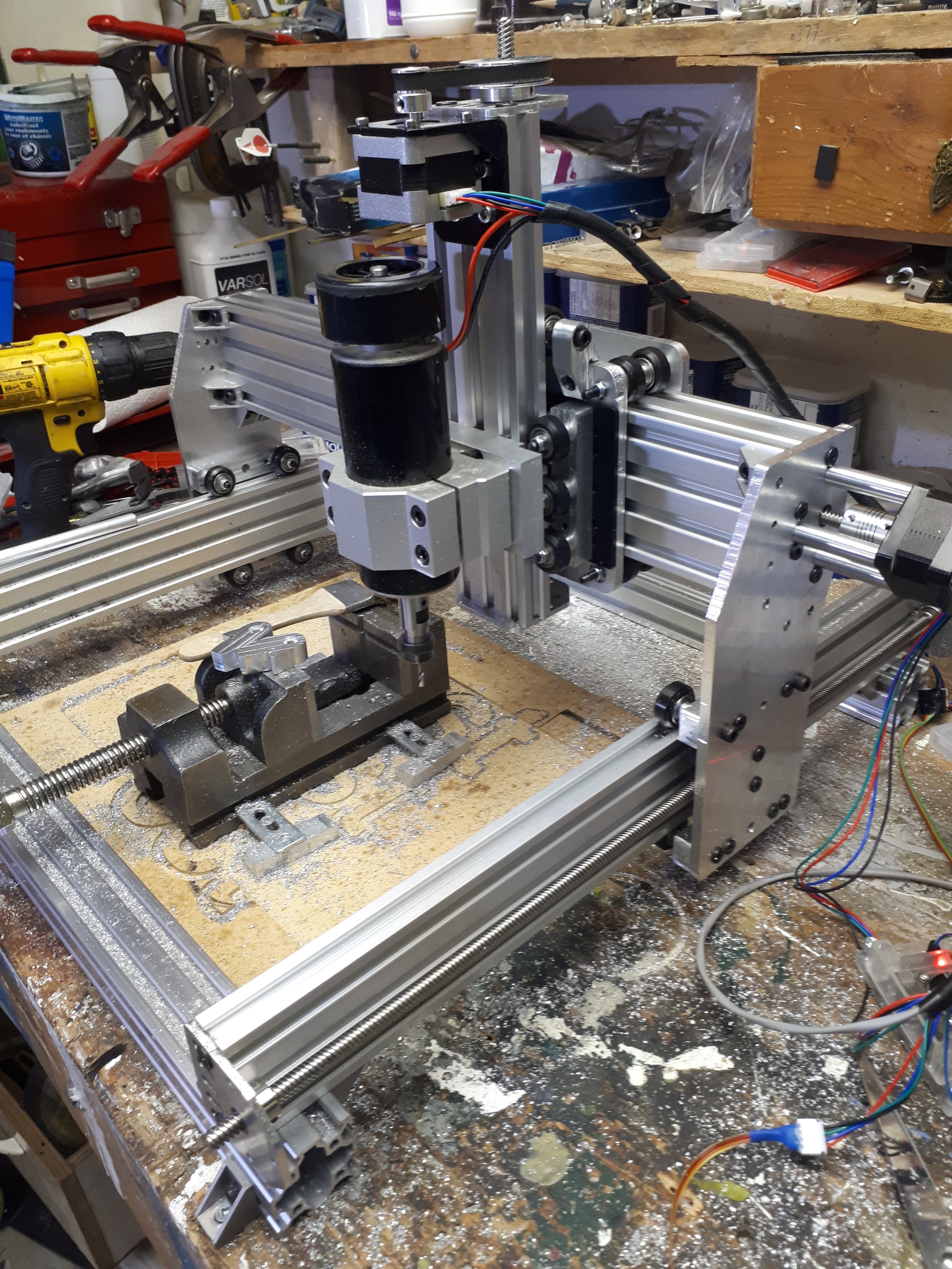

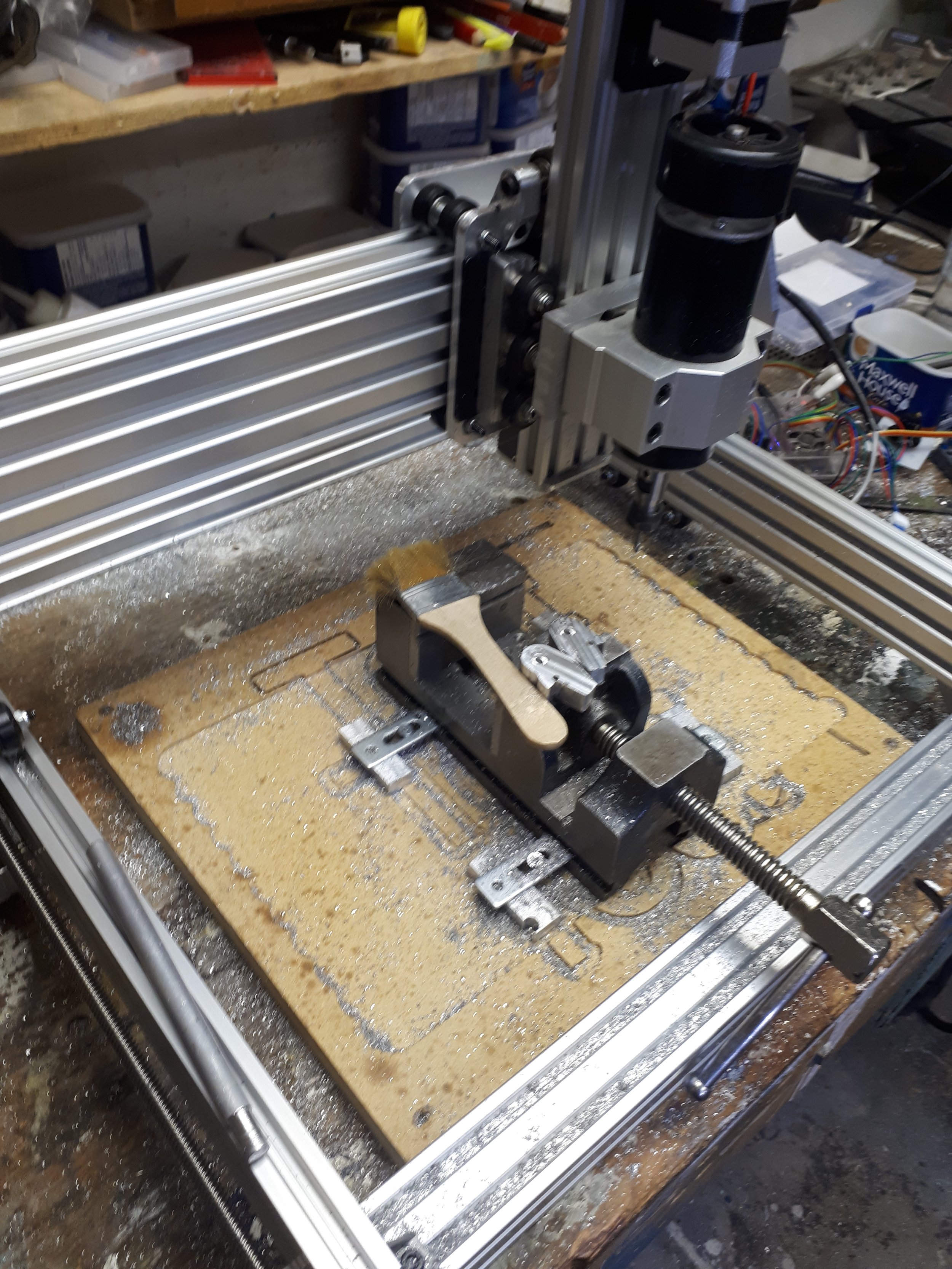

After getting a decent amount of experience with hobby CNC machining using a very cheap and not very capable cheap CNC engraver purchased from Amazon, I was inspired to design and build my own, and fabricate many of the parts myself.

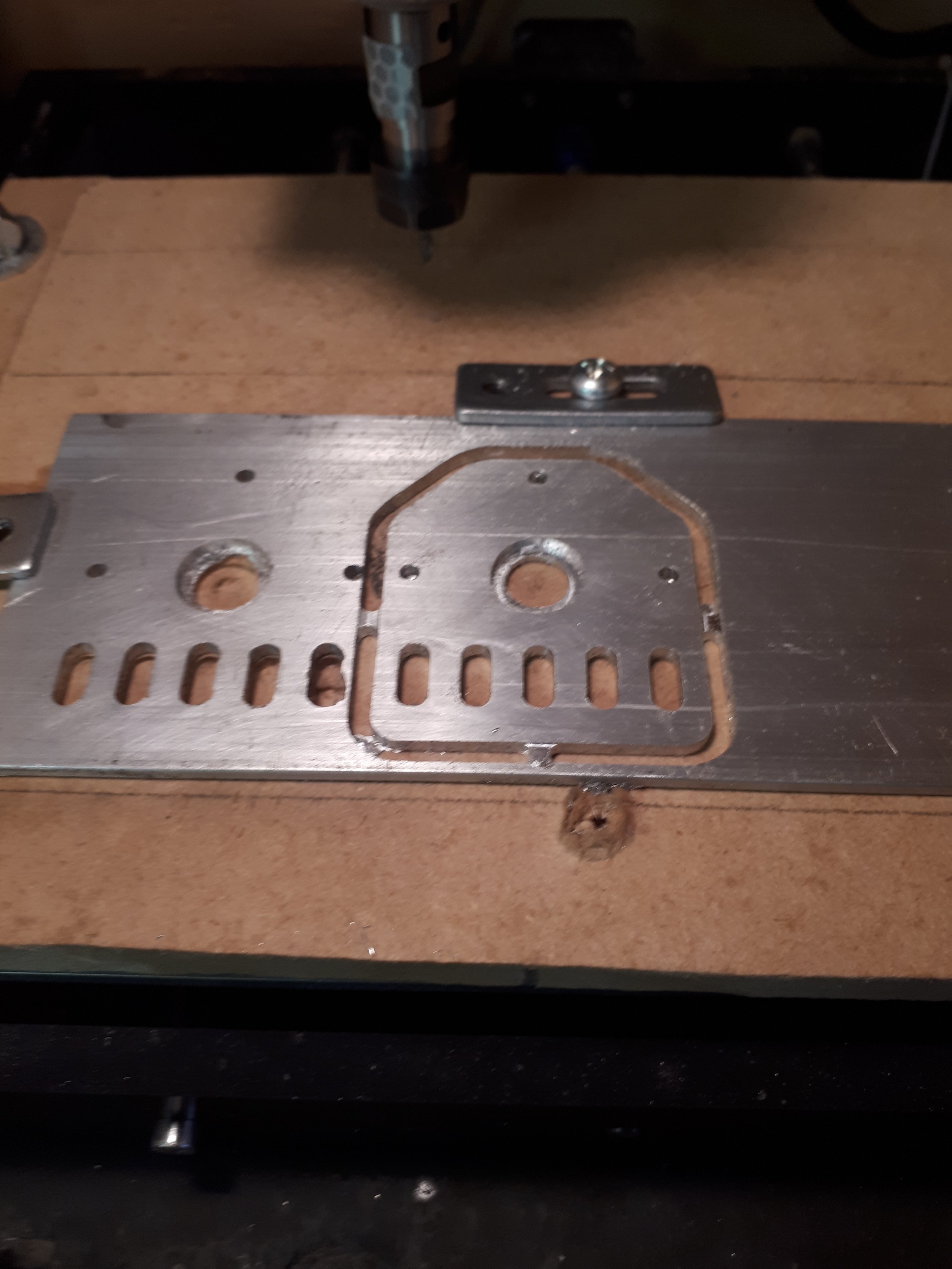

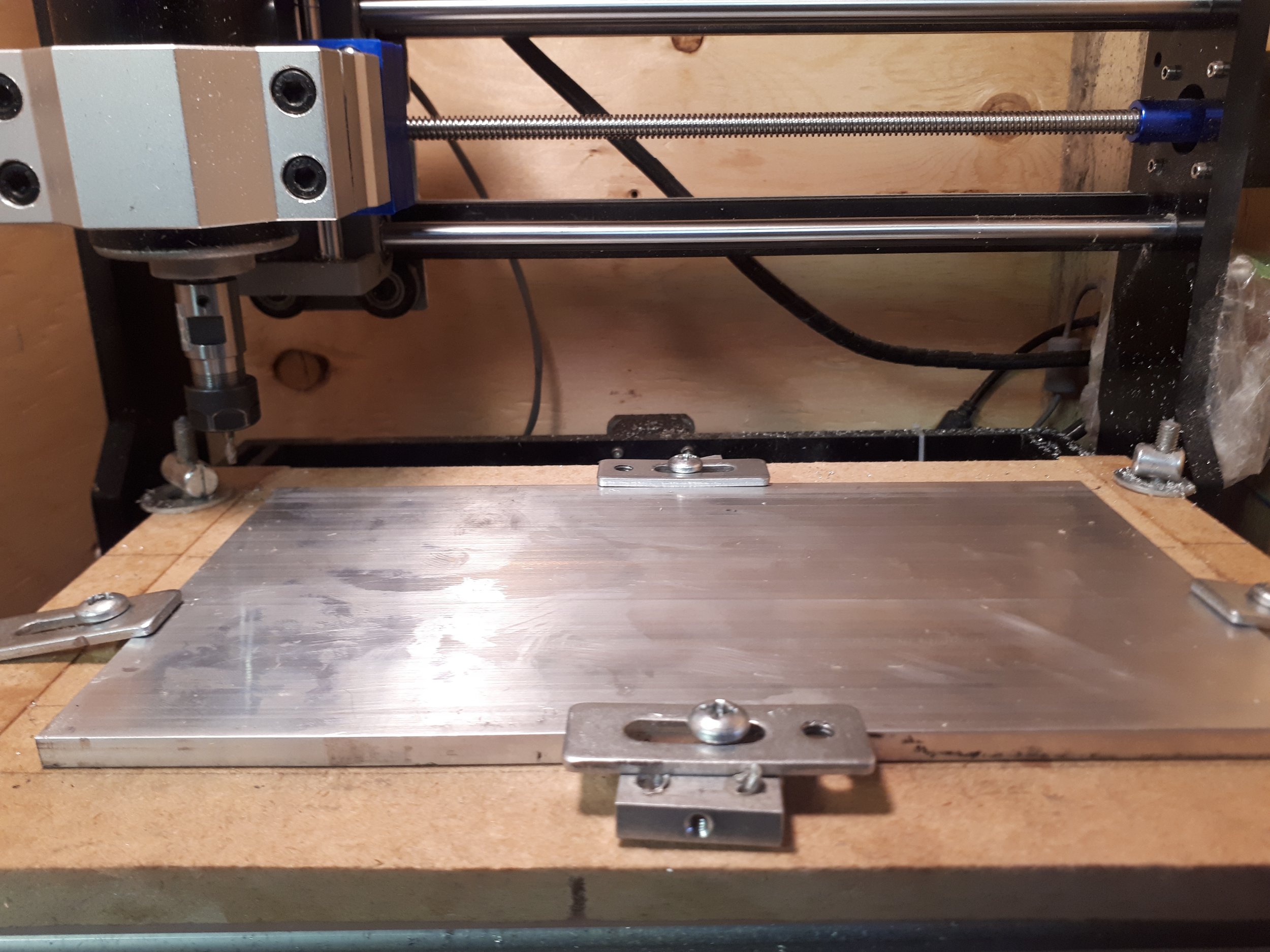

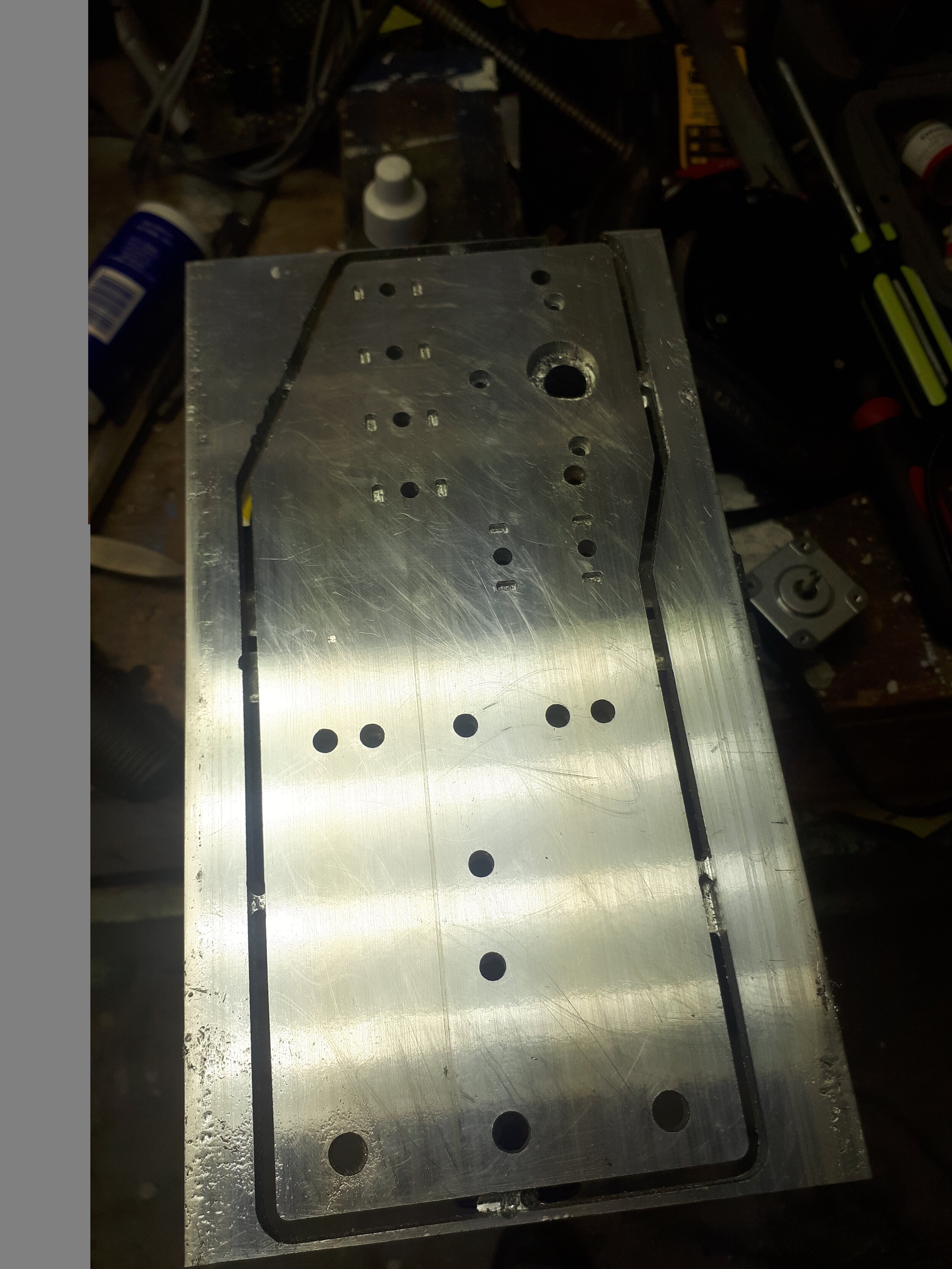

The process of machining the parts on our CNC 3018 was painful, but I am quite happy with the end result.

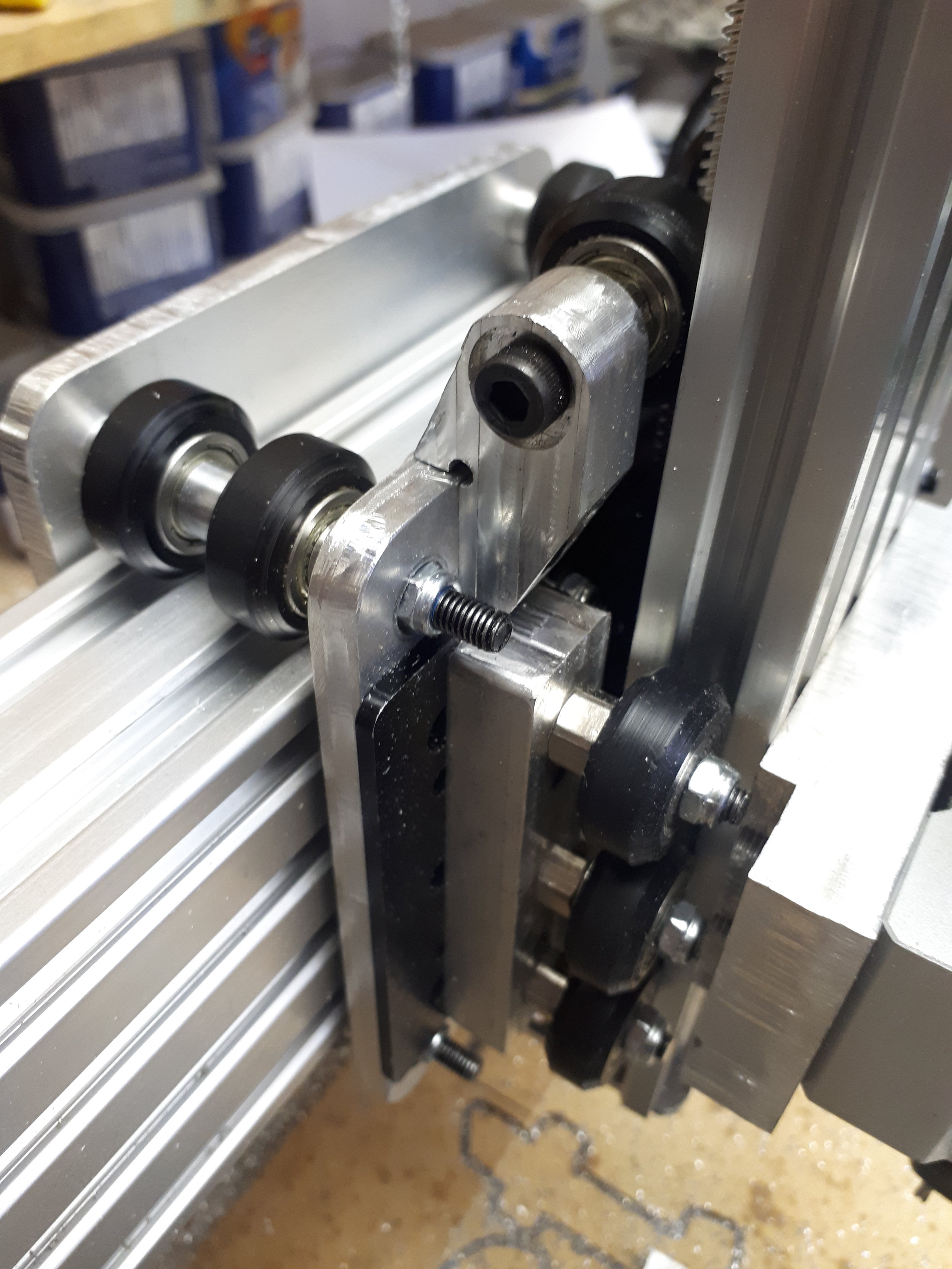

The design was largely inspired by the OpenBuilds Sphynx CNC, but with some simplifications and cost optimizations.

I originally based the build around NEMA 17 stepper motors, but quickly learned that these were not capable of producing enough torque for a machine of this size, especially with lead screw drive. Luckily, it was easy to retrofit with NEMA 23s.

The machine is rigid enough to cut aluminum with ease.